3D print facilities

Dedicated, state-of-the-art, 3D food printers

Whether it’s ravioli, cakes or meat-replacement products, the Digital Food Processing Initiative (DFPI) has in-house extrusion and powder-bed printers for evaluating 3D printing applications for virtually every type of food.

The DFPI encompasses a broad range of extrusion and powder-bed printers, supported by broad knowledge and expertise in food science, (printing) technology and modelling. This allows for detailed investigation of the opportunities and limitations of 3D printing for a given application. How fast, and for what duration, can you print soft candy, for example, before the printed walls start to fall down? And how much detail can you apply when making cake at industrial scales? Our experts develop dedicated processes for printing specific materials and products. Recent projects include a chocolate printer for Mondelez and a pasta printer for Barilla.

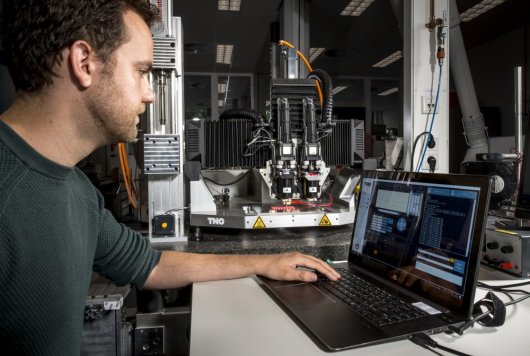

Extrusion printers

We have a broad range of high speed extrusion printers, in which materials are pushed out of a nozzle whilst moving it in the horizontal plane, depositing materials in a layer-by layer fashion, ultimately resulting in a 3D shape. Our printers greatly vary in their extrusion power (from 600 Newton to 20 Kilonewton) and thus are suitable for materials with both low and high viscosities. This could be dough, pasta or potato puree, but also fondant and sugar-based products or cheese/dairy. By combining two material flows in a single nozzle we can extrude a so-called core-shell filament (similar to a hollow spaghetti wires filled with sauce) and subsequently create a 3D shape using this filament. One example of an application includes the next generation of filled pasta

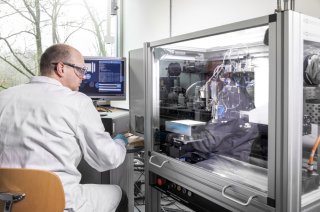

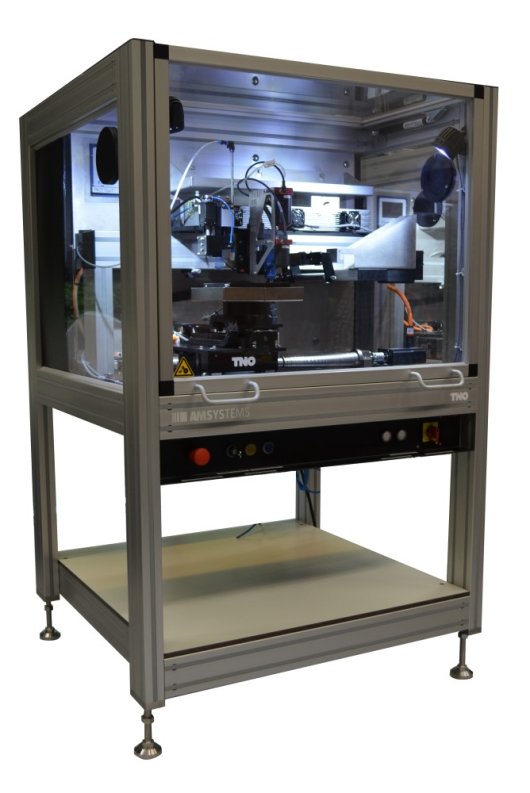

Powder-bed printing

This advanced type of 3D printing is perfect for applications in which base materials are available in a powder form, and in applications where detail is fundamental to the product, such as baked goods, pet food and medicinal capsules.

In Powder-bed printing a thin layer of a powder or powder mixture is deposited on a build platform. Subsequently a binding liquid is deposited on locations where the powder should bind together. This process is repeated layer-by-layer, ultimately resulting in a 3D consolidated object that can then be removed from the surrounding loose powder. In order to locally deposit the droplets of the binding droplet, printing heads are used capable of creating droplets of different sizes (down to several picolitres) and capable of handling liquids with different viscosities. As an alternative or additional consolidation mechanism, a CO2 laser can be used that can write patterns on the powder layers, thus locally melting the material and fusing it together. This combination of using both liquids and laser-generated heat for consolidation offers unique opportunities for consolidation and texture creation, and as such is patented by the DFPI.